ADOBE BRICKS MAKING WORKSHOP

Status: On-going

Location: Battambang, Cambodia

Year: 2025

Client: Phare Ponleu Selpak

Scope of service: Workshop coordinator

Location: Battambang, Cambodia

Year: 2025

Client: Phare Ponleu Selpak

Scope of service: Workshop coordinator

I was invited by Phare Ponleu Selpak, an inspiring Cambodian organisation based in Battambang that works at the intersection of arts, education, and social development, supporting young people and local communities through creative and vocational training.

As Phare prepares to start the construction of a new campus building to host a canteen, they expressed the desire to use adobe bricks for the ground-floor spaces, embracing locally sourced, low-impact materials. For me, this was wonderful news: seeing people curious about and willing to build with earth is always deeply encouraging.

This interest created the opportunity to organise a one-day hands-on workshop dedicated to adobe brick making, aimed at training the community and sharing practical knowledge on earth construction. The workshop focused on understanding soil, preparing mixes, producing bricks, and transmitting skills that can be reused beyond this single project—strengthening local capacity while reconnecting building practices with the land they come from.

SOIL SELECTION

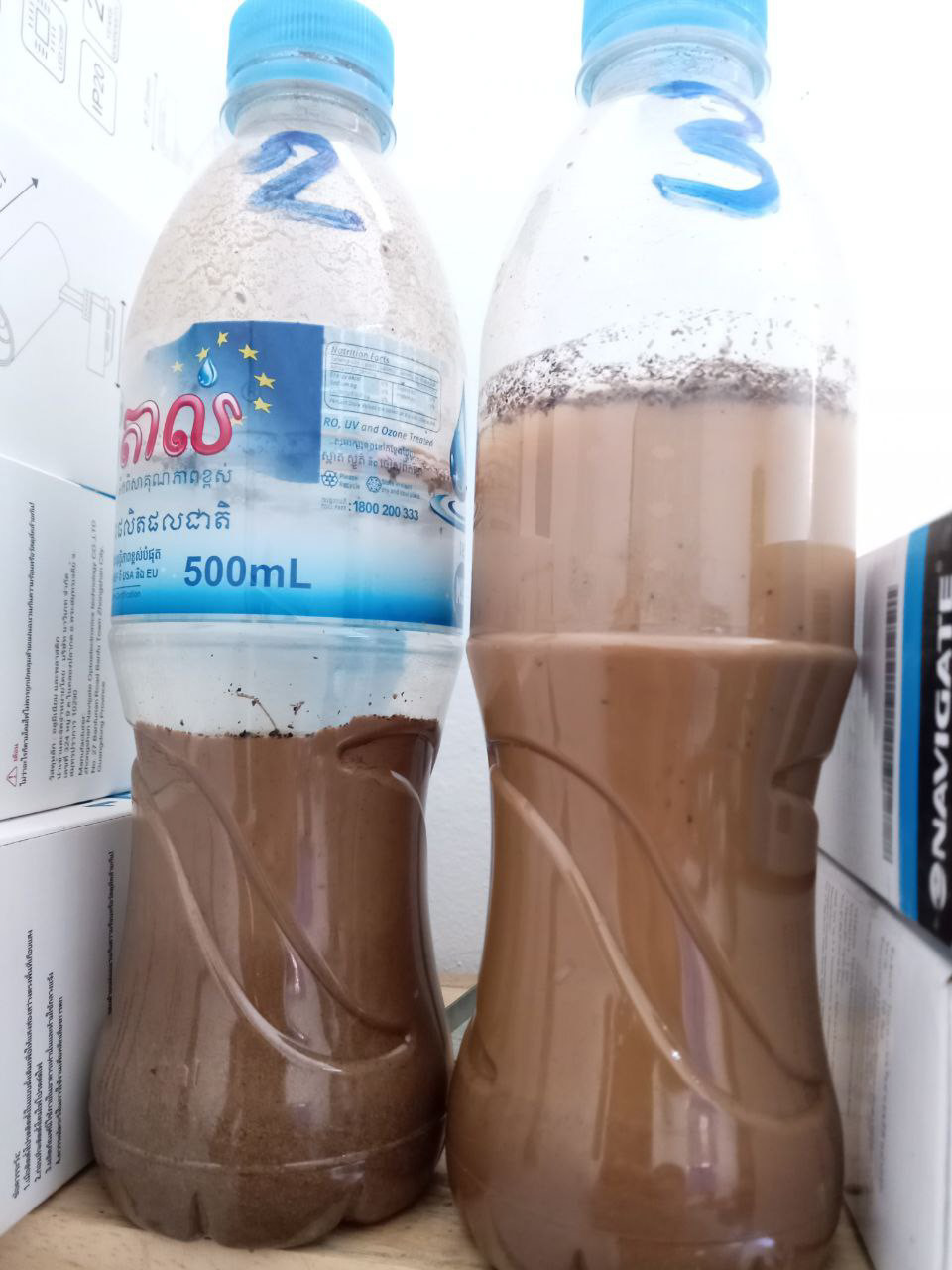

We tested three different types of soil:

- one taken directly from the campus area,

- one from a rice field at 5 m depth,

- one from a rice field at 1 m depth.

To evaluate their suitability, we carried out quick on-site tests — jar tests and the ribbon test. All the soils showed a high clay content, which was great news: this meant the soil itself was suitable for adobe, and we only needed to fine-tune the amount of additional sand.

One challenge we encountered was that all the soils were quite wet, making it difficult to break down large lumps. Although it is usually recommended to dry-mix the ingredients, we adapted our method to site conditions. We decided to pre-soak the soil in a small pit, allowing the clay-rich soil to soften and making it much easier to break apart during mixing.

THE MIX

We chose to experiment with several mixes, producing different types of bricks to test before selecting the final recipe for the building.

The ratios we tested were:

5–3–2 (sand / soil / fibre)

5–4–2

5–5–2

For each ratio, we tested rice husk and straw separately.

Mixing can be done by hand or with your feet, using plastic sheets to help gather the mix toward the centre.

Before filling the moulds, remember to:

Before filling the moulds, remember to:

- wet the mould,

- sprinkle sand at the base to prevent sticking,

When filling the mold compress the edges of the mix well to avoid voids, once the mold is full lift it up vertically when removing it to keep the brick edges straight.

We produced two block sizes: one matching the brick size intended for the building and one standard cube, sized according to laboratory requirements, to be sent for compression and bending strength tests.

At the end of the day, it’s important to clean all tools thoroughly, so they are ready for the next use.

And finally—very important—remember to have fun!